In the dynamic realm of washing machine production, the art and science of metal sheet manufacturing stand as a cornerstone, shaping the durability, structural integrity, and aesthetic appeal of these essential household appliances. As we delve into the intricate world of metal sheet manufacturing within the washing machine industry, we uncover a process that goes far beyond the mere assembly of components; it’s a meticulous craft that ensures each machine emerges as a robust and reliable companion in the daily chore of laundry. From the careful selection of specialized materials to the precise cutting and shaping of metal sheets, this process forms the very foundation of washing machine construction. Skilled artisans employ advanced techniques, including stamping, forming, and welding, to transform raw metal into components that seamlessly come together, embodying both strength and sophistication.

Transforming Metal Sheets into Household Wonders

Washing machines have revolutionized the way we manage our laundry, making the once time-consuming task of washing clothes significantly more convenient and efficient. These indispensable household appliances have become a staple in homes around the world, offering a hands-free solution to the age-old chore of laundry

Evolution of Convenience

The evolution of washing machines is a fascinating journey that spans centuries, transforming an essential domestic task from manual labor to automated convenience. From rudimentary hand-cranked devices to today’s smart, energy-efficient appliances, the evolution of washing machines reflects advancements in technology, design, and consumer needs.

Early Manual Washers

The earliest washing machines were simple hand-operated devices. Early examples included scrub boards and hand-cranked washers, where clothes were manually agitated in water and soap.

Scrub Board (1797)

The earliest form of a washing machine was the scrub board, invented in 1797. This manual device featured a corrugated metal or wooden surface where clothes were vigorously rubbed against ridges to remove dirt and stains. While effective, it required significant physical effort

Washboard (late 19th century)

An improvement upon the scrub board, the washboard had a ribbed surface, usually made of wood or metal. It facilitated better scrubbing and became a common household tool for laundry until the advent of more automated washing machine.

Functionality and Design

Washing machines operate on the simple yet ingenious principle of agitating clothes within a drum filled with water and detergent, effectively removing dirt and stains. Over the years, manufacturers have perfected the design and functionality of these appliances, incorporating advanced features such as various wash cycles, water temperature settings, and spin speeds to cater to diverse laundry needs.

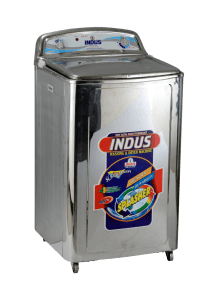

Manufacturing Process of Sheet Metal Washing Machines

The manufacturing process begins with the careful selection of raw materials. High-quality sheet metal, often made of steel or stainless steel, is chosen for its durability and corrosion resistance.

Cutting and Shearing

The sheet metal manufacturers selected sheet undergoes precision cutting and shearing processes. Advanced technologies such as laser cutting or water jet cutting are employed to achieve accurate dimensions, ensuring uniformity in the components

Stamping and Forming

The metal sheets are subjected to stamping and forming processes to create the intricate shapes required for various components like the washing machine drum, panels, and structural elements. Precision is paramount to maintaining the structural integrity of the metal.

Welding and Assembly

Welding is a critical step where different metal components are seamlessly joined together. Skilled technicians use welding techniques to create a robust structure. The assembly process includes integrating components like the drum, frame, and other elements into the main body of the washing machine

Surface Treatment

Post-assembly, the metal surfaces undergo surface treatments to enhance both aesthetics and durability. Processes like polishing, coating, or painting not only improve the visual appeal of the washing machine but also provide protection against corrosion and wear.

Quality Control Measures

Strict quality control measures are implemented at various stages of the manufacturing process. Comprehensive testing ensures that the metal sheets and assembled components meet industry standards for strength, dimensions, and overall quality.

Environmental Considerations

Increasingly, manufacturers adopt eco-friendly practices in sheet metal manufacturing. Recycling initiatives and energy-efficient processes are implemented to reduce the environmental impact of producing washing machines.

Final Inspection

Before the washing machines are deemed ready for market, a final inspection is conducted. This comprehensive check ensures that each unit meets the specified standards, guaranteeing the reliability and performance of the finished product.

Metal Used in the Framework of Washing Machine

The body of washing machines is commonly made from metal, and the type of metal used can vary. Two of the most prevalent metals used in the construction of washing machine bodies are:

Stainless Steel

Stainless steel is highly resistant to corrosion and rust, providing durability and longevity to the washing machine.It offers excellent strength and stability, contributing to the overall robustness of the appliance.

Stainless steel has a sleek and modern appearance, adding to the visual appeal of the washing machine.

- Common Usage

Premium and high-end washing machine models often feature stainless steel bodies.

Galvanized Steel

Galvanized steel is generally more cost-effective compared to stainless steel. It has a protective zinc coating, providing a degree of corrosion resistance.

- Common Usage

Found in a wide range of washing machine models, especially those designed for everyday household use.

These metals are preferred for washing machine bodies due to their durability, resistance to environmental factors like water and humidity, and the ability to withstand the mechanical stresses associated with the appliance’s operation. Manufacturers may also use a combination of metals and other materials to achieve a balance between strength, cost-effectiveness, and aesthetic appeal in the design of washing machine bodies.

Components of Washing Machine

Manual washing machines, often known as hand-cranked or non-electric washing machines, are simple yet effective devices designed for off-grid or low-tech washing. Here are the primary components typically found in manual washing machines

Drum or Tub

Central compartment where clothes are placed for washing.Manual washing machines may have an agitator, paddles, or ribs inside the drum to facilitate the washing process.

Hand Crank or Agitator Handle

Used to manually agitate the clothes in the drum.The rotation of the hand crank creates the necessary agitation for cleaning.

Water Inlet

A port where water can be added manually.Users fill the washing machine with water using a bucket or other means.

Drain Valve or Spout:

Located at the bottom of the machine.Allows users to drain the used water after washing

Detergent Compartment

A designated space for adding detergent or soap manually.Users may agitate the water and soap mixture to create suds.

Types of Washing Machines

The market offers a variety of washing machine types to suit different preferences and living spaces. Front-loading and top-loading machines, as well as compact and portable models, provide consumers with options tailored to their specific requirements.

Top-Loading Machines

In the mid-20th century, top-loading washing machines became popular. These machines featured agitators in a vertical drum, allowing for larger loads and more effective cleaning.

Front-Loading Machines

Advancements continued with the introduction of front-loading washing machines in the latter half of the 20th century. Front-loaders, known for their water and energy efficiency, gained popularity for their ability to handle larger capacities and gentler washing cycles.

Front Load Washing Machines Advantages and Considerations

Efficiency

Front-loaders are generally more water and energy-efficient than top-loaders. They use less water and require less detergent.

Gentler on Clothes

The tumbling action of the drum in front-loaders is gentler on clothes, resulting in less wear and tear.Front-loaders typically offer better cleaning performance due to the drum’s horizontal axis, allowing clothes to be submerged in water for longer periods.

Space Efficiency

Front-loaders can be stacked with a compatible dryer, saving floor space in laundry areas.

Cost

Front-loaders can be more expensive upfront compared to top-loaders, although the price difference has diminished over time.

Bending Over

Loading and unloading may require bending over, which can be a consideration for those with back issues.

Longer Wash Cycles

Some front-loaders have longer wash cycles compared to top-loaders.

Top Load Washing Machines Advantages and Considerations

Ease of Use

Top-loaders are more ergonomically friendly since users don’t need to bend over to load and unload clothes. Generally, top-loaders have shorter wash cycles compared to front-loaders.

Cost

Top-loaders are often more budget-friendly in terms of upfront costs.

Add Items Mid-Cycle

Top-loaders allow users to add forgotten items even after the cycle has started.

Water Usage

Top-loaders typically use more water than front-loaders, potentially leading to higher water bills.

Models with an agitator can be harsher on clothes, leading to more wear and tear over time.

Space Requirements

They may require more floor space, and stacking options are limited.While newer models are becoming more energy-efficient, top-loaders, in general, are still considered less energy-efficient than front-loaders.

Ultimately, the choice between a front-load and top-load washing machine depends on individual preferences, budget considerations, and the specific needs of the user. Each type has its advantages and considerations, and advancements in technology continue to narrow the performance gaps between the two.

Design Considerations

The design of a washing machine goes beyond mere aesthetics; it encompasses a meticulous blend of functionality, efficiency, and user experience. Each aspect of the design is carefully considered to ensure that the appliance not only cleans clothes effectively but also seamlessly integrates into the modern home.

Ergonomics and Accessibility

Efficient design takes into account user comfort and accessibility. The placement of controls, loading and unloading height, and overall usability are crafted to minimize physical strain and make the washing machine experience user-friendly for a diverse range of individuals.

Drum Configuration and Capacity

The design of the washing machine drum is a critical element. Innovations in drum configuration, such as front-loading and top-loading options, cater to different user preferences and spatial constraints. Capacity considerations address the varying laundry needs of households, from compact models for smaller spaces to larger units for families.

Noise Reduction and Vibration Control

Innovations in design extend to minimizing operational noise and vibrations. Anti-vibration systems and soundproofing technologies contribute to a quieter laundry experience, allowing washing machines to seamlessly integrate into various living spaces.

Aesthetics and Integration

Aesthetics are not overlooked, with designers incorporating sleek and contemporary elements to enhance the visual appeal of washing machines. Harmonizing with modern home interiors, washing machines are designed to be more than just functional appliances, becoming an integral part of the overall living space.

Smart Washing Machines making Laundry smarter and easier

A smart washing machine is like having a laundry helper that makes things super easy. Imagine being able to control it with your phone – start, stop, or check how much time is left, all from the comfort of your couch. These machines are smart about washing too. They have special settings for different clothes, so you don’t have to guess what cycle to use. Plus, they’re good with reminders. Ever forget to switch your wet clothes to the dryer? Not with a smart washing machine – it sends you a reminder. These machines also know how to be gentle with energy. They use just the right amount of water and electricity, which is good for your bills and the environment. And here’s the cool part – if something’s not right, the smart washing machine tells you what’s going on. It’s like having a laundry expert right at home, making laundry day a whole lot smarter and simpler.

Future trends in Washing Machine Industry

Smart and Connected Appliances

Integration of IoT (Internet of Things) technology in washing machines allows for remote monitoring, control via mobile apps, and even predictive maintenance. Users can receive alerts, check energy usage, and customize wash cycles from their smartphones.

Energy and Water Efficiency

Increasing emphasis on eco-friendly designs with advanced technologies to minimize energy and water consumption. Future washing machines are likely to have even more efficient wash cycles, reducing environmental impact.3. Sustainable Materials:

Improved Fabric Care

Continued focus on gentler washing mechanisms to protect delicate fabrics. Innovations in drum design and washing algorithms aim to enhance cleaning efficiency while minimizing wear and tear on clothes.

In conclusion, metal sheet manufacturers are the unsung heroes behind the scenes, contributing their expertise to shape the foundation of modern washing machines.

They have evolved from humble beginnings to become essential household appliances that streamline a once laborious task. Their continued innovation reflects a commitment to efficiency, convenience, and environmental responsibility, making them a cornerstone of modern domestic life.

Naa Songs

Naa Songs